Innovations in Pulp Molding Tableware Machine: What’s Next?

- june11433

- Dec 8, 2024

- 2 min read

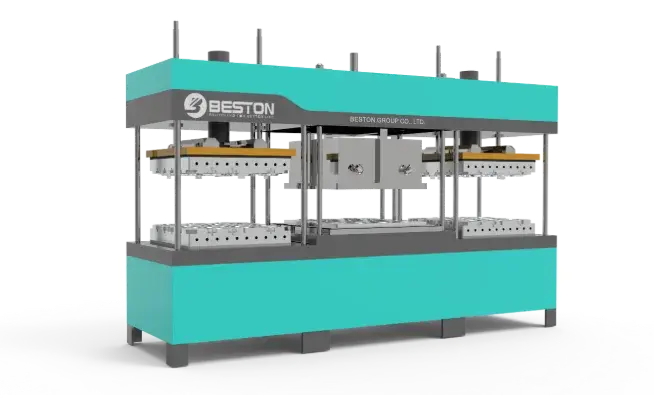

The demand for eco-friendly solutions in food packaging is driving innovation in the pulp molding tableware machine. These machines, designed to transform renewable materials into sustainable tableware, are at the forefront of replacing single-use plastics. With advancements in technology and evolving industry standards, the future of this machinery is brimming with possibilities.

Enhancing Efficiency in Production

One of the critical focus areas for innovation is the optimization of the paper pulp manufacturing process. Traditional methods, while effective, often face challenges related to energy consumption and production speed. Modern machines incorporate automation and intelligent controls to streamline the entire cycle, from pulp preparation to final product molding. These advancements reduce waste, ensure precision, and significantly boost throughput.

Moreover, innovations in mold design are revolutionizing the capabilities of these machines. By using advanced materials and precision engineering, manufacturers can produce tableware with intricate shapes, consistent thickness, and improved durability. This flexibility allows businesses to cater to a diverse range of customer preferences without compromising quality.

Digital Transformation and Automation

The integration of digital technologies into the pulp molding tableware machine is reshaping production lines. Real-time monitoring systems provide detailed insights into performance metrics, enabling operators to identify inefficiencies and maintain optimal operation. Predictive maintenance, powered by machine learning algorithms, minimizes downtime by alerting operators to potential issues before they escalate.

Automation is another key innovation. Robotic arms and conveyor systems now handle tasks such as feeding raw pulp, removing finished products, and packaging, significantly reducing labor dependency. This not only enhances productivity but also ensures uniform quality across batches, critical for large-scale production.Sustainability as a Driving Force

Sustainability remains a cornerstone of developments in pulp molding technology. Machines are now designed to integrate with renewable energy sources, such as solar power or biomass, reducing their carbon footprint. Additionally, water recycling systems within the paper pulp manufacturing process ensure minimal resource wastage. These features align with the growing emphasis on environmental stewardship and circular manufacturing practices.

Biodegradable additives are also being explored to enhance the functionality of molded tableware. Such additives improve moisture resistance, thermal stability, and grease-proofing while ensuring the product remains fully compostable. This combination of performance and eco-friendliness is critical for meeting stringent regulatory standards in global markets.

Expanding Applications and Market Potential

The versatility of pulp molding technology is opening doors to new applications beyond traditional tableware. From custom packaging solutions to specialized products for healthcare and industrial sectors, the potential uses are vast. The ability to mold paper pulp into highly detailed and robust items positions the technology as a viable alternative to plastic across multiple industries.

As consumer preferences shift toward sustainable choices, businesses investing in advanced pulp molding equipment stand to gain a competitive edge. The combination of innovative features, cost-efficiency, and environmental compliance makes these machines a cornerstone of modern manufacturing.

Conclusion

The future of the pulp molding tableware machine lies in its ability to evolve with technological advancements and market demands. By embracing innovations in automation, sustainability, and design flexibility, these machines are poised to redefine the paper pulp manufacturing process. As industries worldwide prioritize eco-conscious practices, pulp molding technology will continue to play a pivotal role in driving the transition to a greener, more sustainable future.

Comments