Technological Advancements in Biodegradable Plates Machine: Enhancing Efficiency and Product Quality

- june11433

- Nov 26, 2024

- 2 min read

The demand for sustainable alternatives to traditional disposable tableware has driven significant advancements in biodegradable plates machine technology. These innovations focus on improving efficiency, enhancing product quality, and reducing environmental impact, offering manufacturers a competitive edge in an eco-conscious market.

Enhanced Automation for Streamlined Operations

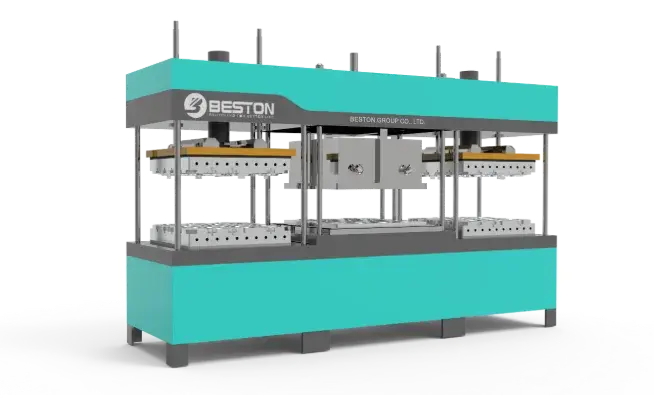

Modern biodegradable plates machine now feature advanced automation systems, which simplify production workflows and minimize human intervention. Automated material feeding, precise molding, and integrated quality control systems ensure seamless operation. These advancements significantly reduce production downtime while increasing overall throughput.

Sophisticated sensors and controllers optimize resource usage by monitoring parameters such as temperature, pressure, and material composition. This ensures consistent quality across production runs, eliminating waste caused by errors in manual processes. Automation also allows operators to manage multiple machines simultaneously, increasing operational scalability.

Energy-Efficient Technologies

Energy consumption has long been a concern in manufacturing. Recent developments in paper pulp moulding machine design address this issue through energy-efficient heating elements and optimized power management systems. Machines now utilize induction heating and infrared technologies, which consume less energy compared to traditional methods.

Additionally, innovative insulation materials reduce heat loss during the molding process, conserving energy and lowering operational costs. These improvements make the machines more sustainable while maintaining high productivity levels.

Advanced Molding Techniques

Precision molding is crucial for producing biodegradable plates that meet industry standards for durability and aesthetics. Recent advancements in molding technology, such as CNC-machined molds and adjustable compression mechanisms, allow manufacturers to create intricate designs with minimal defects.

These enhancements ensure the uniform thickness and structural integrity of the plates, making them more resistant to moisture and heat. Furthermore, the use of biodegradable and compostable materials is optimized by these machines, minimizing material wastage and ensuring a higher yield from raw inputs.

Improved Material Compatibility

The latest biodegradable plates machines are designed to handle a wide range of eco-friendly materials, including bagasse, bamboo pulp, and wheat straw fiber. These machines are equipped with adaptive settings to accommodate the varying properties of these materials, ensuring compatibility without compromising efficiency.

For instance, adjustable temperature and pressure controls allow precise processing of different biomaterials, reducing the risk of degradation during production. This versatility enables manufacturers to diversify their product offerings and cater to niche markets with specific requirements.

Integration of Smart Technologies

The integration of IoT (Internet of Things) and AI (Artificial Intelligence) technologies has further revolutionized the biodegradable plates machine industry. Smart machines can now monitor performance metrics in real-time, providing operators with actionable insights to optimize processes.

Predictive maintenance systems powered by AI help identify potential issues before they cause machine failures, reducing unplanned downtime. Additionally, remote monitoring capabilities allow technicians to adjust settings and troubleshoot problems without being physically present, ensuring uninterrupted operations.

Conclusion

Technological advancements in biodegradable plates machines are transforming the industry by enhancing efficiency, improving product quality, and expanding material compatibility. From automation and energy-efficient designs to smart technologies and advanced molding techniques, these innovations provide manufacturers with the tools to meet growing demand while upholding environmental responsibility. As sustainability continues to shape consumer preferences, these machines stand at the forefront of eco-friendly manufacturing solutions.

Comments