The Evolution of Pulp Molding Tableware Machine: Innovations and Market Trends

- june11433

- Jan 6, 2025

- 3 min read

The pulp molding industry has experienced significant advancements over the past few decades, particularly in the production of tableware. The evolution of pulp molding tableware machines has been driven by increasing demand for sustainable and biodegradable packaging alternatives. Innovations in material processing, machine efficiency, and product versatility have positioned pulp molding as a key player in the sustainable packaging sector. This article explores the developments and market trends shaping the future of pulp molding tableware machines.

From Basic Molding to Advanced Precision

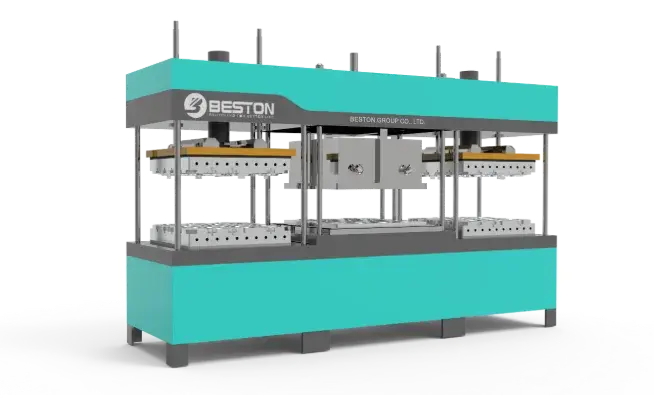

Early pulp molding machinery were designed primarily for simple, functional products such as egg trays. Over time, however, advancements in machine technology have allowed for the production of more intricate, high-quality tableware items, including plates, bowls, and trays. These machines have evolved from basic, manual processes to highly automated systems capable of producing a wide range of tableware products with precision and speed.

Today’s pulp molding tableware machines incorporate advanced technologies such as automated drying systems, temperature and humidity control mechanisms, and energy-efficient motors. These innovations have not only improved production speed and consistency but also reduced waste, making them more eco-friendly and cost-effective. The ability to manufacture complex shapes and customized designs has expanded the market potential of pulp molded tableware, allowing manufacturers to meet the diverse needs of the foodservice industry.

Material Advancements: The Rise of Sugarcane Bagasse

In parallel with advancements in machinery, the materials used for pulp molding have also evolved. Traditionally, recycled paper and cardboard were the primary materials used in pulp molding. However, the growing demand for sustainable and renewable alternatives has led to the rise of sugarcane bagasse as a key material in the production of pulp molded tableware. The sugarcane bagasse tableware making machine is a prime example of how the industry is leveraging this abundant and eco-friendly raw material.

Sugarcane bagasse is the fibrous residue left after the extraction of juice from sugarcane. As a byproduct of sugar production, bagasse is abundant and can be repurposed into high-quality pulp for molding. Using sugarcane bagasse for tableware not only reduces waste but also provides a biodegradable alternative to plastic, which is increasingly being banned in many regions. The adoption of this material has been a game-changer in the pulp molding industry, offering an environmentally friendly solution without compromising on durability or functionality.

Market Trends and Consumer Preferences

The market for pulp molded tableware has been significantly influenced by changing consumer preferences. With growing environmental awareness, consumers and businesses are increasingly turning to sustainable alternatives to replace single-use plastics. The global push toward banning plastic straws, plates, and cups has created a surge in demand for eco-friendly tableware options. Pulp molded products, particularly those made from sugarcane bagasse, have emerged as a preferred choice due to their biodegradability, strength, and versatility.

As the demand for eco-friendly tableware continues to rise, manufacturers are focusing on improving the design and functionality of their products. Innovations such as leak-proof coatings, microwave-safe materials, and improved texture are enhancing the appeal of pulp molded tableware. Additionally, customization options, such as embossed logos and unique designs, are becoming more common as businesses seek to differentiate themselves in the market.

Efficiency and Cost-Effectiveness

The growing market for pulp molded tableware has also driven improvements in the efficiency and cost-effectiveness of pulp molding tableware machines. Modern machines are designed to optimize energy consumption, reduce labor costs, and maximize material yield. The integration of advanced automation systems allows for faster production cycles and greater consistency in product quality. These improvements have made pulp molding machines more accessible to small and medium-sized enterprises, opening up new opportunities for businesses to enter the sustainable packaging market.

Moreover, the use of sugarcane bagasse as a raw material has helped lower production costs. As bagasse is a byproduct of the sugar industry, it is relatively inexpensive and widely available, making it a cost-effective alternative to other raw materials.

Conclusion

The evolution of pulp molding tableware machines reflects the growing demand for sustainable, eco-friendly alternatives in the packaging and foodservice industries. Innovations in material technology, such as the use of sugarcane bagasse, along with advancements in machine efficiency and design, have significantly expanded the potential of pulp molded products. As consumer preferences shift toward environmentally responsible options, pulp molded tableware is poised to become a dominant force in the market. The ongoing advancements in this field will continue to drive the industry forward, offering businesses a viable solution for meeting the increasing demand for sustainable packaging.

Comments